Concreto estampado: qué es, ventajas, moldes, colores y precios

La popularidad del concreto estampado no es una coincidencia. Sus innumerables ventajas convierten a este recubrimiento decorativo en uno de los más utilizados para realizar cualquier tipo de obra. Un material de constrcción resultado de la combinación de diferentes elementos: aglomerante, agregados, agua y algunos aditivos

El resultado de su mezcla da como resultado pavimentos de concreto estampado y paredes verticales que destacan por su gran dureza y resistencia, pero también por su vistosidad. Una estética de lo más atractiva que se da gracias al amplio abanico de diseños que ofrecen los moldes de concreto estampado que se estampan sobre la superficie que se desea renovar.

¿Qué es el concreto estampado?

El concreto estampado es una técnica decorativa que consiste en estampar moldes sobre la superficie de concreto fresco que imitan a la perfección todo tipo de materiales. Los dibujos, texturas y colores que se pueden obtener son infinitos.

El concreto estampado, como también se le denomina al concreto impreso, es un pavimento continuo de bajo relieve y con la superficie

pigmentada capaz de simular las piezas y texturas más variadas: adoquines, ladrillo, piedra, pizarra, baldosas e incluso madera, entre otros.

Un material de construcción empleado especialmente en el ámbito de la pavimentación de terrazas, parques, jardines, garajes, centros comerciales, entradas a viviendas residenciales o en el contorno de las piscinas. De ahí que se conozca como pavimento estampado, ya que esta técnica se emplea principalmente sobre pavimentos horizontales.

La versatilidad que permite este pavimento continuo decorativo y su durabilidad, son algunas de las claves de su éxito. Un concreto estampado que se

aplica tanto en superficies interiores como en superficies exteriores. Sin embargo, cabe destacar que también se pueden estampar moldes sobre paramentos

verticales. Esta otra técnica recibe el nombre de concreto estampado vertical.

Ventajas del concreto estampado

El concreto estampado no tiene límites en lo que a formas y colores se refiere. Una personalización en el diseño de la que no pueden presumir todos los materiales. Asimismo gracias a su capacidad de imitar el parqué, la piedra, el ladrillo o la madera, entre otros, se pueden crear proyectos únicos.

A estas ventajas del piso de concreto estampado, hay que sumar su maleabilidad, resistencia y durabilidad. Por ello presenta campos de aplicación tan variados. Garajes, terrazas, centros comerciales, viviendas y muchas otras superficies. Fachadas, paredes y pisos de concreto estampado que no requieren de limpieza y mantenimiento especiales.

Durabilidad y resistencia

El concreto estampado es uno de los pavimentos más duraderos que existen gracias a su alta resistencia al tráfico. De ahí que se apueste tanto por este material para recubrir calles, parques, garajes o entradas a zonas residenciales. También es un revestimiento decorativo que resiste los cambios continuos de temperatura y los rayos UV. Se adapta a las diferentes condiciones climáticas, incluso a las heladas. Si se lleva a cabo una correcta aplicación y un uso adecuado, un piso de concreto estampado puede llegar a durar más de 20 años.

Gran variedad de acabados

El concreto estampado es altamente personalizable. Ofrece una multitud de acabados, formas y texturas dependiendo de los moldes de

concreto estampado utilizados. Pero también de los pigmentos elegidos para dar color al molde en cuestión. Existe la posibilidad de combinar

varios pigmentos para obtener resultados finales aún más espectaculares. Una versatilidad gracias a la cual se utiliza como pavimento

pero también como revestimiento de paredes y fachadas.

Rápida ejecución

La instalación del concreto estampado es rápida y sencilla. Al tratarse de un mortero continuo, se reducen los tiempos de ejecución en comparación con otras alternativas del mercado. Las formas geométricas más complejas, requerirán de un mayor plazo.

Bajo mantenimiento

Preservar el óptimo estado del concreto estampado no es tan exigente como otros materiales. Basta con lavar la superficie de vez en cuando para evitar la acumulación de la suciedad. Y renovar la capa de barniz cada 2 o 3 años, especialmente en pavimentos que sufren bastante desgaste por la rodadura de vehículos.

Beneficios del concreto estampado

Acabados personalizados

Los moldes de concreto estampado ofrecen infinitas combinaciones y texturas

Resistencia a ciclos de frío-calor

Los cambios de temperatura extremos no afectan al concreto estampado.

Impermeable y antideslizante

Con el uso de moldes y barnices específicos, el concreto estampado garantiza un acabado impermeable y antideslizante.

No decolora

Los colores del concreto estampado están compuestos por pigmentos resistentes a la luz solar. Por eso, con el paso del tiempo ni se degradan ni se decoloran.

Uniformidad

El concreto estampado encaja perfectamente en todos los terrenos, incluso en aquellos que presentan irregularidades o formas variadas.

Evita el crecimiento de la hierba mala

El concreto estampado, al formar un pavimento estilo losa y no tener juntas y espacios, impide el crecimiento de la maleza.

Versatilidad en interiores y exteriores

Se puede emplear de varias maneras tanto en interiores como en exteriores. Tanto como sistema de pavimentación como de revestimiento de paredes y fachadas.

Larga vida útil

El piso de concreto estampado tiene mayor resistencia y durabilidad con respecto a otros muchos materiales.

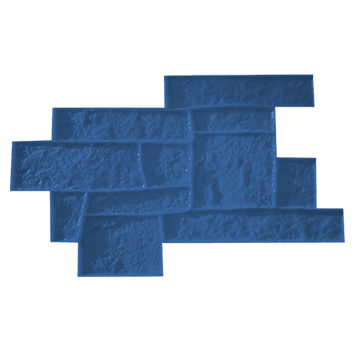

Moldes para concreto estampado

Los moldes son un elemento básico para llevar a cabo esta técnica decorativa. Su estampación en los pavimentos y revestimientos verticales es lo que permite obtener texturas y dibujos de lo más variados.

Las soluciones decorativas que ofrecen nuestros más de 150 moldes de concreto estampado son ilimitadas. Una gama de abanicos, moldes adoquines, moldes baldosas, moldes calzadas, moldes ladrillos, moldes losas o moldes piedras.

Moldes de concreto estampado en constante creación para ofrecer patrones y diseños cada vez más creativos si cabe. Lograr acabados como la piedra

irregular, los adoquines clásicos e incluso la madera no puede ser más fácil que con IMACEM.

Conócelos a todos y deja volar tu imaginación.

Ver moldes

Colores del concreto estampado

El concreto estampado es un revestimiento continuo en el que se pueden combinar todos los colores existentes y por existir. Desde colores neutros como el blanco, el negro, gris o beige, hasta tonalidades más intensas y atrevidas como el rojo, verde o azul.

Para colorear el concreto estampado se emplean pigmentos inorgánicos, porque son resistentes a los álcalis, a la radiación solar y a la intemperie. Factores climatológicos a los que se ve expuesto este material de construcción. Por eso es tan importante contar con colores de calidad que eviten sorpresas desagradables como la decoloración con el paso del tiempo del pavimento o fachada.

En Topciment hemos creado cuatro líneas distintas de colores de concreto estampado. Pigmentos que dotan de color al mortero transformando su aspecto y que pueden utilizarse sin preocupaciones en exteriores. Arcocem, que así se llama la familia de nuestras pastas pigmentarias, son muy resistentes a los efectos de la luz solar así como a los productos de limpieza.

Con nuestros tintes podrás teñir el concreto estampado con total seguridad. Blanco, gris, plata, negro, café, azul, verde o rojo son solo algunos de los muchos colores de concreto estampado que podemos ofrecerte. Asimismo, muchos de nuestros productos presentan su propia gama de colores.

Ver colores

Renueva múltiples espacios con concreto estampado

El concreto estampado es una alternativa a materiales de arquitectura más tradicionales. Nos referimos a la madera, al terrazo, a la cerámica. Una técnica decorativa que conforma una elección más económica de realizar y también de mantener en el tiempo.

Un recubrimiento que permite jugar con el relieve y el estampado y es más indicado para ser colocado en exteriores, especialmente en pisos de áreas públicas. En función del método de aplicación y la práctica que se le vaya a dar, existen cuatro tipos de concreto estampado.

Pisos de concreto estampado en exteriores: calles, banquetas, parques, terrazas, jardines, patios, centros comerciales, estacionamientos, entradas a zonas residenciales, etc.

Pisos de concreto estampado en interiores: aunque son menos comunes, en los últimos años su uso ha aumentado en casas, polideportivos, restaurantes, hoteles y locales comerciales.

Concreto estampado en piscinas: la resistencia a la humedad del concreto estampado, su carácter antideslizante y un toque decorativo único lo convierten en uno de los materiales más recomendados para recubrir el entorno de la piscina. Por ello el concreto estampado en piscinas es tan popular.

Concreto estampado vertical: lo encontramos en fachadas, muros y paredes de casas residenciales y edificios patrimoniales como museos. El contraste estético del concreto estampado vertical es espectacular. Su proceso de ejecución se diferencia un poco del sistema de pavimentación.

PAVIMENTOS IMPRESOS

Crea espacios de ensueño con pavimentos impresos. Apuesta por esta técnica decorativa e innova en espacios comunes y casas residenciales. Renueva parques, jardines, plazas, terrazas, centros comerciales, parkings de estacionamiento y mucho más.

Ver galería

IMPRESO VERTICAL

¿Quién dijo que el concreto estampado es solo para pisos? Reforma paramentos verticales de viviendas privadas y negocios, fachadas e incluso edificios históricos como museos. Logra acabados finales de lo más singulares con el concreto estampado vertical.

Ver galería

PISCINAS

CONCRETO ESTAMPADO

Pocas soluciones decorativas son tan sobresalientes para renovar la playa de la piscina como el concreto estampado. No solo por la gran variedad de diseños y texturas disponibles, sino por la posibilidad de acabados impermeables y antideslizantes que el concreto impreso para piscinas ofrece.

Ver galería

Cómo aplicar el concreto estampado

1. Preparar la superficie

2. Verter el concreto

3. Alisar, nivelar y fratasar

4. Esparcir el endurecedor de color

5. Alisar

6. Aplicar el desmoldante

7. Imprimar el molde impreso

8. Remover el desmoldante

9. Limpiar la superficie

10. Aplicar el barniz

Continuar

Preguntas frecuentes sobre concreto estampado

Aparte de ser un material de construcción muy estético, el concreto estampado destaca por su versatilidad.

El concreto estampado se aplica principalmente en pisos. Algunos de los pavimentos estampados más comunes los encontramos en calles, banquetas, centros comerciales, parques, plazas, jardines, estacionamientos al aire libre, patios o entradas a zonas residenciales.

Pero también hay pisos de concreto estampado en el interior de grandes naves industriales y superficies como centros deportivos, locales comerciales o restaurantes. Esto sin mencionar el concreto estampado para piscinas, uno de los tipos de aplicación más recurrentes del concreto estampado.

A pesar de no ser muy conocido, esta solución decorativa puede ser aplicada en fachadas y en paredes tanto de espacios interiores como exteriores. Esto es lo que se conoce comúnmente como concreto estampado vertical.

La aplicación del concreto estampado varía dependiendo de la superficie a revestir. La aplicación del pavimento estampado, tanto interior como exterior, se realiza de una manera determinada; mientras que la aplicación del concreto estampado vertical se ejecuta de otra distinta. Enesta página te explicamos el paso a paso de cada una de ellas.

La aplicación del concreto estampado varía dependiendo de la superficie a recubrir. La aplicación del pavimento estampado, tanto en interiores como exteriores, se lleva a cabo de una forma concreta; mientras que el concreto estampado vertical se aplica de diferente manera. En esta página explicamos el paso a paso de cada una de ellas.

No es coincidencia que cada vez más personas opten por el concreto estampado en piscinas por su condición de antideslizante. Una de las opciones más recomendables para cubrir tanto el borde de la piscina como los alrededores y evitar caídas. Siempre y cuando se use, eso sí, un

barniz que le proporcione este acabado.

Adicionalmente, es más atractivo visualmente ya que el pavimento estampado es capaz de imitar la piedra o la madera, entre otros materiales nobles.

La impermeabilidad es una de las particularidades de los pavimentos de concreto estampado, pudiendo ser aplicado en áreas expuestas a la lluvia ya que no permite el paso del agua, evitando así las filtraciones y los problemas derivados de ellas. Una cualidad por la que las piscinas de concreto estampado son tendencia. No obstante, es muy importante aplicar un barniz para darle esta propiedad.

El precio del concreto estampado depende de múltiples factores. Desde la calidad de los materiales empleados o los moldes de concreto estampado, hasta los colores elegidos, la mano de obra y la complejidad de la obra a realizar. Pero también de las texturas y acabados finales. De esta manera, el precio por metro cuadrado del concreto estampado varía mucho en función de estos elementos. De manera aproximada, en España el costo por m2 se encuentra entre los 40 y 100 euros.

La resistencia y la durabilidad son dos características que comparten el concreto estampado y el concreto pulido. Ambos son pavimentos ideales para las superficies de alto tráfico por su gran resistencia e inalterables a los cambios de temperatura extremos. Depende del uso, la superficie que se vaya a recubrir y las necesidades particulares de cada persona, es más

recomendable utilizar un tipo de concreto u otro. Estas son las principales diferencias entre el pavimento estampado y el pavimento pulido:

- En el impreso, los moldes se utilizan para estampar diferentes dibujos y texturas en la superficie, por lo que las formas que se aplicaron con estos moldes se pueden encontrar en la capa superficial del concreto estampado. Por el contrario, la capa superficial del concreto pulido es totalmente lisa y continua ya que no se utilizan moldes.

- El grosor que presenta la capa de concreto pulido es ligeramente superior al del concreto estampado.

- El concreto pulido es un material con una gran demanda para las superficies interiores, sobre todo en viviendas particulares. En cambio, encontramos pavimentos de concreto estampado tanto en exteriores como interiores e incluso concreto estampado vertical en paredes, fachadas o muros.

- Las técnicas de acabados son totalmente diferentes. Mientras que el pavimento impreso tiene un acabado con relieve y texturas, el concreto pulido ofrece un acabado mucho más liso y sin

texturas ya que no requiere de moldes.

A pesar de que no es muy usual, debido a que el uso del concreto estampado está más extendido en superficies exteriores, también se puede emplear en interiores sin ningún tipo de problema de dos maneras. El primero, como pavimento; y el segundo, en fachadas, muros y paredes.

Si con el tiempo te cansas del concreto estampado, puedes removerlo sin ningún problema. La manera más práctica es emplear la superficie existente como pavimento de concreto y poner encima lo que quieras. Por ejemplo, podrás colocar adoquines, gres, loza, azulejo o microconcreto, entre otros.

Otra forma para remover el concreto estampado, aunque un poco más brusca y que se utiliza principalmente en grandes obras, es la de destruir la superficie con un martillo compresor o perforador.

La duración de la instalación del concreto estampado, depende de múltiples factores: los metros cuadrados a cubrir, los acabados que se quieren conseguir, la superficie donde se aplicará el concreto estampado o el grado de inclinación de dicha superficie, ya que es necesario nivelarlo. Teniendo en cuenta todos estos factores, la instalación del piso de concreto estampado suele durar aproximadamente una semana.

El concreto estampado no requiere de una limpieza exhaustiva, aunque eso depende del nivel de suciedad en el pavimento o en la pared vertical. En principio, es suficiente con limpiar la superficie cada 3 meses. Recomendamos usar nuestro limpiador detergente

Ecoclean Pro. Enjuagar a continuación con agua a presión.

El mantenimiento del concreto estampado no requiere de mucha complejidad, ya que es un tipo de revestimiento muy resistente cuya durabilidad puede incluso superar los 20 años. En el caso de que con el transcurso del tiempo el pavimento estampado haya perdido algo de color o empiece a hacerse

notar el cemento, es recomendable aplicar una resina mezclada con el pigmento del suelo.

Aunque esta es la opción más usada, como especialistas recomendamos aplicar Covercem® Stone. Un mortero de renovación estético y que tiene un aspecto muy natural que es ideal para renovar el concreto que haya perdido el color o la dureza. Además, ofrece una mayor resistencia que aplicando únicamente una resina.

Pueden aparecer grietas o fisuras en el concreto estampado por diversas razones: desde una carga excesiva sobre el tereno, una malla de acero mal posicionada o incluso la ausencia de esta, hasta una compactación deficiente del terreno antes del colado del concreto, entre otros.

A continuación, explicamos el paso a paso para reparar grietas o fisutas en el concreto estampado:

- Limpiar en profundidad el pavimento o la pared vertical que necesita ser reparada, con especial énfasis en el interior de la fisura o grieta. Si es necesario, aspira el polvo que se haya podido acumular dentro.

- Rellenar la grieta o fisura generosamente con una masilla de reparación para concreto. Esta puede ser flexible (masilla acrílica o de poliuretano) o cementicio. Si es necesario, abre bien la grieta para permitir la entrada del producto de reparación.

- Ha llegado el momento de renovar el acabado superficial del concreto estampado. Para ello, aplicar Covercem® Stone o Covercem® Monocrom en el color que queramos.

- En el caso de usar el Covercem® Monocrom, es necesario realizar previamente una decapación de la superficie con nuestro Ecoclean Stripper. Después tendrás que limpiar el pavimento con agua a presión.

- Cuando el Covercem® esté completamente seco, aplicar inmediatamente los selladores Sealcem® WT o Sealcem® DSV dependiendo del brillo y acabado necesario.

Aunque el concreto estampado es un pavimento continuo decorativo muy resistente, con el paso del tiempo puede haber una pérdida de color o de brillo en sus acabados debido a la erosión, a la lluvia, al sol o a un mal uso del mismo.

Un problema que tiene fácil solución. A continuación te explicamos cómo recuperar el color o brillo del concreto estampado:

- Limpia bien el área donde quieras renovar el concreto estampado. Para ello, recomendamos el limpiador detergente Ecoclean Pro, siguiendo las indicaciones previamente dadas.

- Una vez que el piso o pared esté completamente seco, aplica los selladores Sealcem WT T o Sealcem DSV en función del brillo o acabado deseado. Se aplicarán como mínimo dos capas del sellador elegido. En el caso específico del barniz Sealcem® WT, se puede pigmentar con nuestra gama de colorantes Arcocem®.

El último paso de la técnica decorativa del concreto estampado consiste en aplicar un barniz. Un producto fundamental que no solo protege el nuevo recubrimiento de impactos y condiciones meteorológicas, sino que también prolonga su buena apariencia.

Un barniz que, en ocasiones, enaltece el color del piso o la pared vertical a la vez que aumenta su resistencia. Como norma general, esta resina se aplica cada dos o tres años. El objetivo no es otro que recuperar el brillo perdido a lo largo de los años y reforzar su resistencia.

En Topciment hemos desarrollado una línea de barnices específicos llamada Sealcem®. En esta página

te explicamos cómo barnizar el concreto estampado, paso a paso.

Ya que el concreto estampado en una superficie texturizada, es necesario decaparlo para remover el sellado o el barniz de la superficie. Para ello, usa nuestro producto Ecoclean Stripper. Los pasos a seguir son:

- Primero, debes decapar el recubrimiento de concreto estampado para dejarlo en las mejores condiciones posibles. Con un rollo o cepillo, aplica nuestro gel decapante Ecoclean Stripper hasta recubrir totalmente la superficie.

- Cuando la superficie esté perfectamente decapada, se cubrirá completamente con plástico durante 1 hora. Se debe garantizar este período para evitar que se seque el decrapante y para favorecer que actúe en profundidad.

- Una vez que se proceda a quitar el plástico, se limpiará la superficie con agua a presión.

- Después de comprobar que el concreto estampado está seco, es la hora de sellar la superficie nuevamente con nuestros barnices Sealcem® WT o Sealcem® DSV o con nuestra gama de productos Covercem®.

Un mal uso del concreto estampado puede ocasionar un deterioro significativo con el paso del tiempo. En caso de necesitar una reparación considerable, este es el protocolo de actuación:

- Limpiar bien el área a reparar. Se recomienda usar el limpiador detergente Ecoclean Pro o Ecoclean Construction. Dependiendo del grado y tipo de suciedad existente, usa uno u otro. Deja que el limpiador actúe entre 5 y 15 minutos. Después, cepilla con un cepillo de cerdas y enjuaga con agua a presión.

- Cuando la superficie esté completamente seca, es el momento de reparar el concreto estampado. Recomendamos el mortero Covercem® Stone en el color elegido. Aplica dos capas, dejando un tiempo de secado de entre 4 y 8 horas entre cada aplicación, cubriendo bien la superficie. Déjalo secar entre 24 y 48 horas después de la segunda aplicación.

- En caso de querer un acabado más fino, debes aplicar los consolidantes minerales Covercem® Monocrom o Covercem® Restaura para reparar el concreto estampado dañado. Previamente, se decaparía la superficie con Ecoclean Stripper. Después de limpiar la superficie con agua, procederíamos a cubrir la superficie con dos aplicaciones de Covercem®. Dejamos secar 2 horas entre aplicaciones, 24 horas después de la segunda y justo antes de aplicar el sellador.

- Una vez que el Covercem® Stone, Covercem® Monocrom o Covercem® Restaura esté seco, aplica los selladores Sealcem® WT or Sealcem® DSV dependiendo del brillo o acabado deseado.

- Si además de reparar el concreto estampado buscas darle un carácter impermeable al recubrimiento, aplica dos capas de Covercem® Xtrem. Déjalo secar entre 4 y 8 horas entre cada aplicación. Después, pule. Este consolidante mineral, ideal para pulir, mejorará la protección de la superficie frente al agua y frente a los agentes atmosféricos.

En el caso de un recubrimiento de concreto estampado deteriorado y una falta de color, pintarlo puede ser la mejor opción para que luzca como el primer día. Es muy importante evaluar los daños para tener el tratamiento adecuado.

Si por ejemplo el pavimento estampado o la pared se ha decolorado o quieres cambiar el color por el motivo que sea, recomendamos dos métodos para pintar el concreto estampado. Usar nuestra pintura Sealcem® DSV Colour o bien nuestros pigmentos y pastas pigmentarias Arcocem®.

Ahora bien, si además de la pérdida de color la superficie acusa de daños mayores y por tanto requiere de una reparación, el método sería muy distinto. En este caso particular, habría que emplear la familia Covercem®. Se tratan de recubrimientos consolidantes minerales que no solo subsanan los desperfectos del piso de concreto estampado o fachada, sino que le otorgan color para recuperar así la vigorosidad del concreto estampado inicial.