Ready-to-use microcement for high decoration | Efectto Quartz

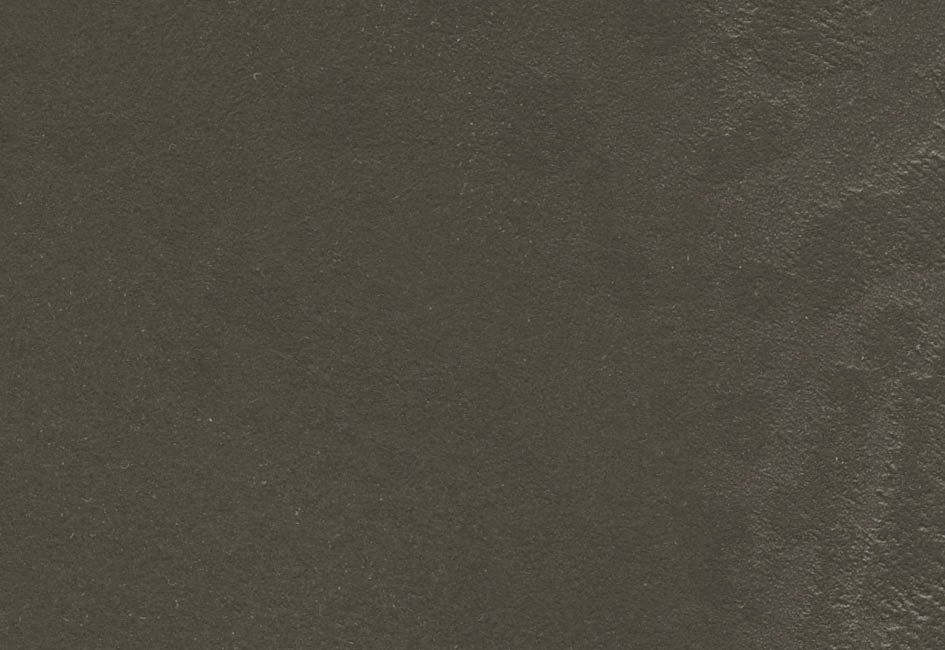

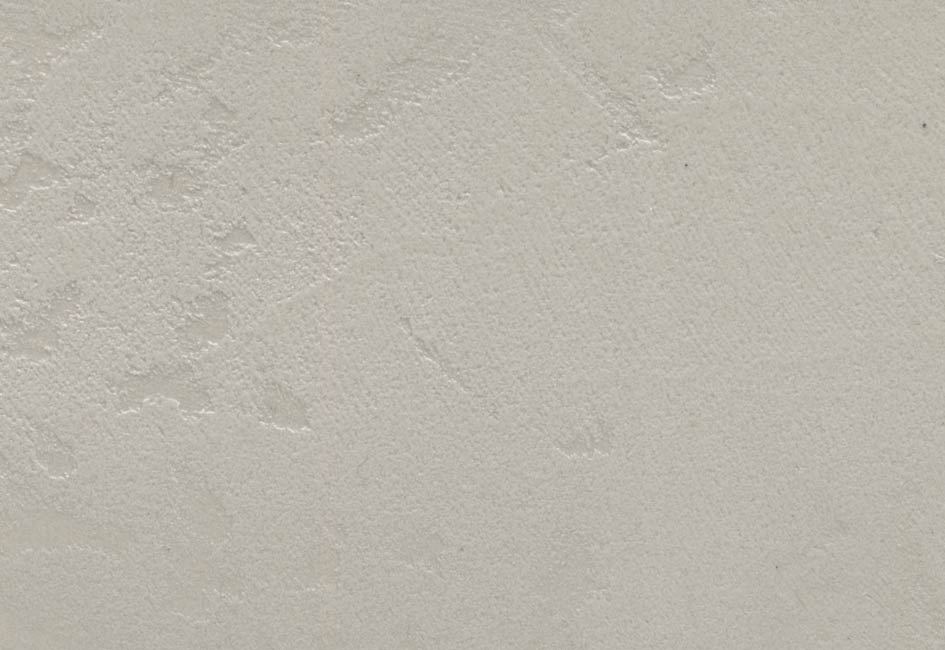

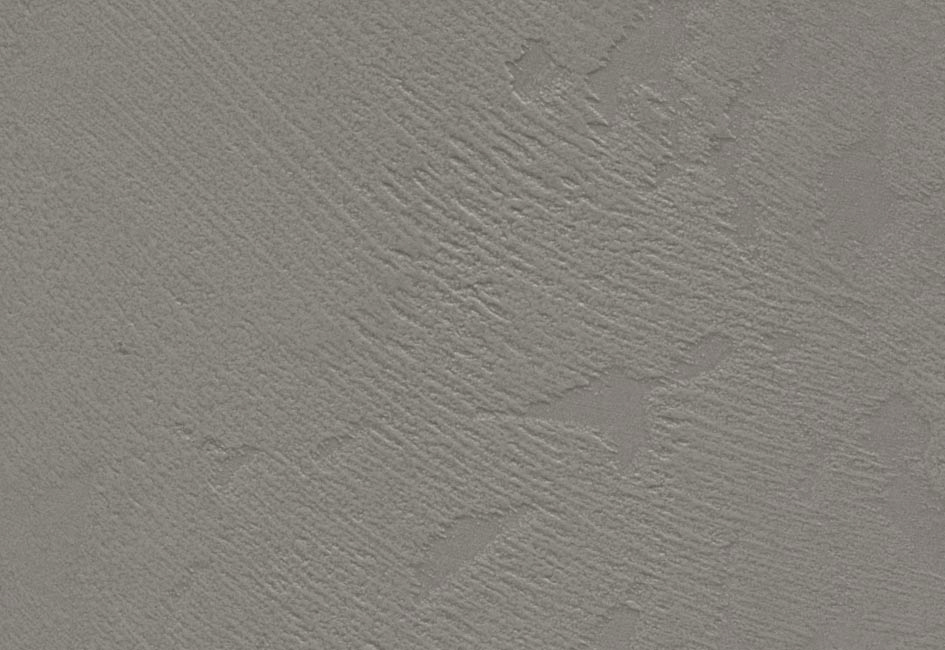

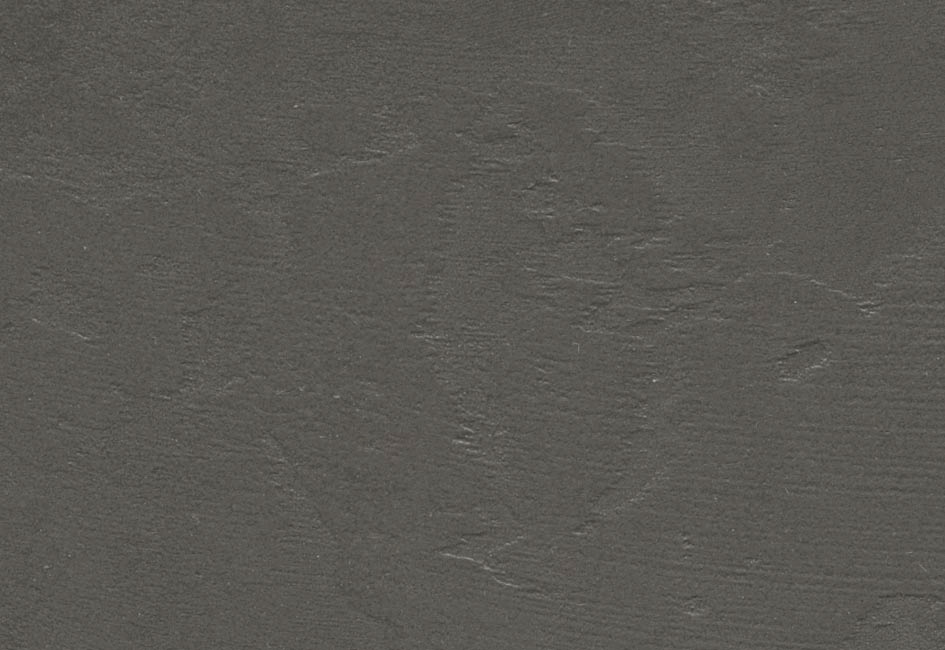

Efectto Quartz is the ready-to-use microcement line that offers highly decorative continuous finishes.

A continuous coating designed for professionals who want to be more productive, increase the speed of microcement application and avoid debris. For all these reasons, Efectto Quartz ready to use microcement is the best choice for work on houses that are already inhabited.

This ready-to-use microcement stands out for its low thickness which, together with its great adherence, allows it to be applied on practically any substrate. It’s a coating suitable for vertical surfaces and light-traffic horizontal surfaces in interior spaces.

A product that boasts excellent workability, does not yellow, and does not require the use of mesh for application due to its extraordinary flexibility. It is an exceptional decorative solution for covering old surfaces made of concrete, ceramics, plaster, drywall, cement, and many more options.

Efectto Quartz ready-to-use microcement is available in a wide colour palette featuring 48 different shades, all in line with current design trends. All of them are distinguished by their natural look.